Kraft Liner Paper Making Line

Leizhan provides Living Paper Making Machine, Kraft/Testliner Paper Machine, High-grade Cultural Paper Machine, Fluting/Corrugated Paper Machine, Coating Board Paper Machine. Also, we can supply matched paper pulp equipment and solutions for you. Contact us: paperproductmachine@gmail.com

-

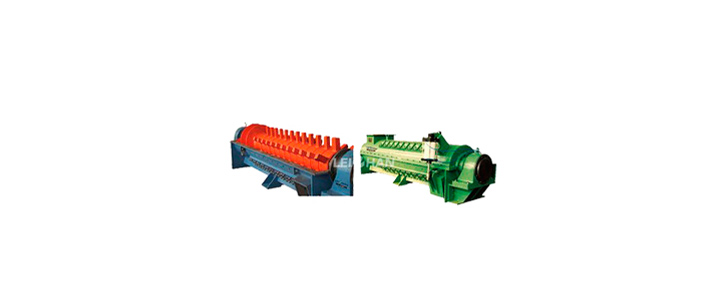

Double Disc Refiner for Pulping Line

-

The Double Disc Refiner is an advanced milling equipment used in pulp production to refine wood pulp and ensure the necessary fiber properties for high-quality paper products. With an emphasis on sustainability, Leizhan’s refiner is designed to consume less energy compared to traditional refining machines.

-

-

Inflow Pressure Screens from Leizhan

-

Inflow pressure screen is a vital piece of machinery in the paper-making process. It functions as a filtration system that separates individual fiber from impurities and non-fiber materials. Leizhan’s inflow pressure screens employ advanced technology to achieve superior filtration rates.

-

-

High-Capacity Kraft Paper Making Machine

-

Leizhan’s high-capacity kraft paper making machine is at the forefront of paper production technology, designed to maximize efficiency and output. Understanding that each manufacturer has unique needs, Leizhan offers customizable solutions for their kraft paper making machines.

-

-

Pulp Making Machine Drum Pulper

-

Drum Pulper is a specialized piece of equipment used in the paper pulp production process. It efficiently separates and processes raw materials—such as waste paper and wood chips—into pulp, which serves as the foundation for producing various paper products.

-

-

High-Efficiency Kraft Paper Manufacturing Line Machine

-

Leizhan provides complete kraft paper production lines, from pulping to finishing, ensuring superior paper quality and optimized kraft paper production efficiency. Leizhan’s paper making line adopts energy-saving design, optimized drying and pressing systems, which can reduce steam and electricity consumption.

-

-

Vibrating Screen for Stock Preparation Line

-

Leizhan is at the forefront of this innovation, providing high-quality vibrating screens designed to optimize the stock preparation process. In the context of stock preparation, it is primarily used to remove impurities and ensure that the pulp is free from contaminants before it goes into the subsequent stages of paper production. The vibrating screen enhances the overall efficiency of the paper-making process by enabling better material handling and management.

-

-

Pulping Machine Kneader in Paper Production

-

The pulping machine kneader is an essential piece of equipment in the pulp production process. It plays a critical role in breaking down raw materials—such as wood chips, waste paper, or agricultural residues—into a workable pulp slurry. The kneader is engineered for maximum efficiency, reducing processing time while ensuring optimal fiber separation and breakdown.

-

-

200TD Kraft Liner Paper Production Line

-

Leizhan is a leading paper making machinery manufacturer with extensive experience in paper making machinery manufacturing. Our kraft paper has a multi-nip pressing configuration (3-4 nip zones) to remove the water from the paper to the maximum extent. The shoe press technology makes the paper dryer before drying (up to 48-50%).

-

-

Kraft Liner Paper Processing Machine

-

Leizhan is a leading manufacturer of advanced kraft liner paper processing machines, designed to produce high-strength, durable packaging paper for corrugated boxes, industrial packaging, and shipping materials. Our kraft liner paper machines feature advanced pressing and drying systems for optimal moisture control.

-

-

High-Performance Vibrating Screen for Paper Mill

-

Leizhan’s Vibrating Screen is specifically designed to meet the demanding needs of modern paper mills, offering unmatched performance, durability, and ease of operation. Its advanced design ensures that even the finest impurities are effectively removed, resulting in cleaner pulp and higher-quality paper.

-

-

Energy-Saving Pressure Screen in Pulping Line

-

Energy-Saving Pressure Screen is a highly advanced screening device used in the pulping process to separate fibers and remove impurities. The pressure screen is designed with precision-engineered rotor and screen basket configurations, ensuring optimal fiber separation and impurity removal.

-

-

Elevating Pulp Quality with High Density Cleaner

-

Leizhan is a pioneer in paper machinery manufacturing, has introduced the High Density Cleaner, a cutting-edge solution designed to optimize the pulp cleaning process. This innovative pulping machine ensures the removal of impurities, enhancing pulp quality and boosting overall paper production efficiency.

-